JIANGSU HAOHUA INDUSTRY GROUP

Tel: +86-512-58220050

Fax: +86-512-58810865

E-mail: sales@haopipe.com

MSN: haopipe@hotmail.com

Skype: haopipe

seamless stainless steel and nickel-based alloy tubes and pipes are our everyday passion and our history at salzgitter mannesmann stainless tubes. as early as 1885 reinhard and max mannesmann invented a rolling process for the production of seamless steel tubes in remscheid, Germany. in the 1890‘s they developed it futher until it reached marketability: the production method they invented was the pilger process, which still is widely in use today.

Our group integrates the tradition of three seamless stainless steel worlds (Mannesmann, Dalmine and Vallourec). Resulting in “High AlloyStainless” from this international merger in 1994, High Alloybecame a part of Salzgitter group in 2003 and adjusted its name to Salzgitter Mannesmann Stainless Tubes in 2008.

With an international network of plants and offices, we are a global top player in our markets and a consistently reliable business partner, ensuring quick and customer focused answers to changing market requirements.Our customers profit from one of the most comprehensive product ranges in our business:

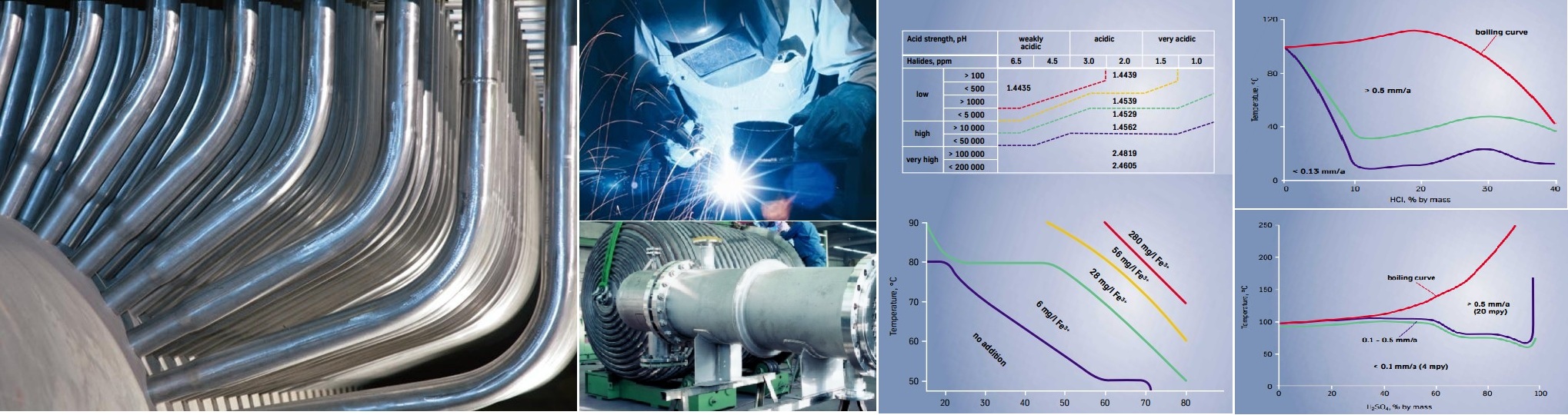

· from small instrumentation tubing to large pipe sizes with outside diameters from 6 to 250 mm (from 0.24 up to 9.84 inches) and with wall thicknesses from 0.5 up to 50 mm (from 0.02 up to 1.97 inches)· in materials from standard austenitic stainless, duplex and super-duplex steels to highly sophisticated nickel-based alloys – this variety offers highest corrosion resistance, heat resistance and/or high-temperature, high-strength materials.

We combine high quality products for critical environments with efficient and reliable services: our customers thus enjoy a supportive personal account management.

Ongoing cycles of investment ensure that we work according to the latest technical standards. This gives us the trustworthiness to equip the so called “critical spots” of customers‘ plants, products and processes with the special qualities of our tubes and pipes.

Typically, these “critical” service conditions are defined e.g. by

· high temperatures

· high pressure

· aggressive media (acids or basic)

Characterization of heat resistant materials

Table 1 lists the international designations for selected SMSTTubes materials having improved austenite stability. The stability of the austenite in CrNi and CrNiMo steels is achieved by increasing the nickel content over that of standard 18/8 CrNi and 18/8/2 CrNiMo steels, and more especially by additions of nitrogen, which is particularly effective in promoting the austenite stability.

Typical properties of austenitic heat resistant materials include:

· high creep rupture strength above 550°C

· outstanding resistance to high-temperature corrosion and oxidation

· excellent processing characteristics.

High-temperature corrosion and oxidation

Although the loads that act on tubes in heat resistant materials are many and varied, they can be determined by calculation and can be controlled by appropriate materials selection and correct design. However, experience has shown that external influences occur during the service life of plants, which cannot be predicted at the planning and design stage, as they largely result from the actual operating conditions to which the tubes are exposed.

Most of these influences are related to high-temperature corrosion. Within the limits of the permissible temperature ranges,heat resistant austenitic steels generally exhibit excellent resistance to combustion gases with sufficient excess air.

To withstand the service conditions, the sensitivity of the material to oxidation on the steam-side is an important factor.

Regarding the scaling behaviour of superheater pipes in a conventional power station, the following influencing factors have to be taken into account when considering flue gases:

· flue gas temperature

· tube wall temperature

· tube position

· heat transfer by radiation

· fuel composition

· flue gas composition (e.g. reducing streaks)

· firing principle (e.g. dry or fused ash handling)

· ash content in flue gas

· erosion

These external influencing factors often determine the service life of a plant.

Corrosion-Resistant Alloy

|

product/thickness |

equivalent |

1t |

1.6t |

2t |

3t |

4t |

5t |

6t |

8t |

10t |

12t |

14t |

16t |

20t |

25t |

30t |

35t |

40t |

50t |

remark |

|

Alloy 59 |

Alloy59(VDM) |

|

|

o |

O |

O |

O |

O |

O |

O |

|

|

|

O |

|

|

|

|

|

ASTM B575 |

|

Alloy C-276 |

Hastelloy |

O |

O |

O |

O |

O |

O |

O |

O |

O |

O |

|

O |

O |

O |

O |

|

O |

O |

ASTM B575 |

|

Alloy C-22 |

Hastelloy |

O |

O |

O |

O |

O |

O |

O |

O |

O |

O |

O |

O |

O |

O |

O |

O |

O |

O |

ASTM B575 |

|

Alloy B-2 |

Hastelloy |

|

|

O |

O |

O |

O |

O |

O |

O |

O |

|

|

O |

|

|

|

|

|

ASTM B333 |

|

Alloy 400 |

Monel 400 |

|

|

O |

O |

O |

O |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

ASTM B127 |

|

Alloy 825 |

Incoloy |

|

|

O |

O |

O |

O |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

ASTM B424 |

|

Alloy 20 |

Carpenter |

|

|

O |

O |

O |

O |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

ASTM B463 |

|

Alloy 201 |

Nickel 201 |

O |

|

O |

O |

O |

O |

O |

O |

O |

O |

|

O |

O |

|

|

|

|

|

ASTM B162 |

Heat-Resistant Alloy Inventory

|

product/thickness |

equivalent |

1t |

2t |

3t |

4t |

5t |

6t |

8t |

10t |

12t |

14t |

16t |

20t |

25t |

30t |

40t |

50t |

remark |

|

Alloy 625 |

Inconel |

|

O |

O |

O |

O |

O |

O |

O |

O |

|

|

O |

|

|

|

|

ASTM B443 |

|

Alloy 600 |

Inconel |

|

O |

O |

O |

O |

O |

O |

O |

O |

|

O |

O |

|

O |

|

|

ASTM B168 |

|

Alloy 601 |

Inconel |

|

O |

O |

O |

O |

O |

O |

O |

O |

|

|

O |

|

O |

|

|

ASTM B168 |

|

Alloy 800H/HT |

Incoloy |

|

|

O |

O |

O |

O |

O |

O |

O |

|

O |

|

|

|

|

|

ASTM B409 |

Titanium ASTM B265

|

product/thickness |

equivalent |

1t |

2t |

3t |

4t |

5t |

6t |

8t |

9t |

10t |

12t |

15t |

18t |

20t |

remark |

|

Grade 2 |

|

|

O |

O |

O |

O |

O |

O |

O |

O |

O |

O |

O |

O |

ASTMB265 |

Duplex/Super Austenitic Stainless Steel

|

product/thickness |

equivalent |

1t |

2t |

3t |

4t |

5t |

6t |

8t |

9t |

10t |

12t |

14t |

16t |

20t |

25t |

30t |

remark |

|

254SMO |

|

|

O |

|

O |

|

O |

|

|

O |

O |

|

|

|

|

|

|

|

185N |

|

|

|

O |

O |

O |

O |

O |

|

O |

O |

|

|

O |

|

|

ASTM A240 |

|

DP3W |

|

|

|

O |

O |

O |

O |

O |

|

O |

O |

|

O |

O |

|

|

|

|

329J4L |

|

|

|

O |

O |

O |

O |

O |

O |

|

O |

|

O |

|

|

|

|

|

NAS254N |

SUS 836L |

|

O |

O |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

|

Contact us about thickness which are not listed in this inventory.

|

Friendly link:

Stainless coils tubing |

Titanium Alloy steel pipes |

U tubes |

Finned tubes |

Ferritic Stainless Steel Pipes |

Duplex Stainless steel pipes |

Austenitic stainless steel pipes |

Nickel Alloy steel pipes |

JIANGSU HAOHUA INDUSTRY GROUP Tel: 0086-512-58220050 Fax:0086-512-58810865 E-mail: sales@haopipe.com Add: No.17,Southeastern Avenue, Economic Development Zone (South Area),Zhangjiagang City, Jiangsu Province, China. |